03. Our resources

Production resources

Our expertise allows us to meet our customers’ needs by integrating a full range of metalworking technologies with an appropriate project management.

All you need

Prototypes, small, medium and large series

Wide variety of processed materials: aluminum alloys, hard metals (titanium, stainless steel, Inconel), copper alloys, nickel and cobalt based alloys…

Supply chain and subcontracting management

Cutting

3 cutting / punching laser machines,

2 2D/3D cutting laser machines.

-

Punching and laser cutting machine -

Laser cutting -

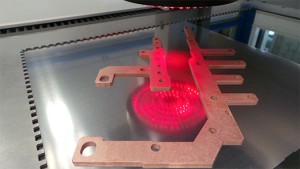

EDM (electrical discharge machining)

Bending – Rolling

10 NC folding machines up to 8 axes, length 3200 max.,

5 rolling machines, width 1250 max.

-

Bending press 130T -

Bending press 85T -

Rolling machine -

Bending press -

Bending press workshop

Presses

6 hydraulic presses, up to 120 tons,

19 mechanical presses, up to 120 tons.

-

Mechanical press – 80T -

Mechanical press – 80T -

Mechanical press – 160T -

Mechanical press – 160T -

Electric press -

Hydraulic Press workshop

Welding

1 YAG laser welding unit, 500x500x1000 max.,

4 spot welding machines,

3 glove boxes for TIG welding on titanium,

12 TIG welding stations,

1 MIG welding station.

-

Spot welding machine -

Spot welding machine -

Spot welding machine -

Welder in a booth -

Laser welding robot head -

Glove boxes -

Titanium welding station with glove box

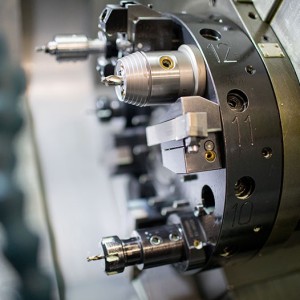

NC Machining

3 electrical discharge machines 1000x800x300 max.,

6 – 3 and 4 axis machining units,1500x500x650 max.,

1 – 5 axis machining units, 700x600x500 max.,

3 NC turning machines up to ø250 max.,

2 surface grinders, 600×300 max.

-

3-axis machining center -

3-axis machining center -

5-axis machining center -

Robodrill -

automatic KNC turning machine

Finishing

3 roller planers

2 deburring/grinding machines,

Tribofinishing (vibration, drums, centrifuge),

Marking via electrolytic, laser, micropercussion, engraving technologies.

-

laser engraving machine -

Deburring machine -

Deburring machine -

Tribofinishing drums

Treatments, varnishing and painting

5 heat treatment ovens,

1 automatic degreasing line,

1 varnishing and painting booth with oven.

-

FISA degreasing lines

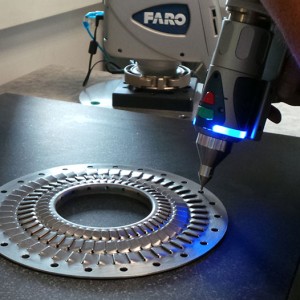

Inspection

Fluorescent Penetrant Inspection line S2/S3 NADCAP qualified,

4 three-dimensional measuring machines 1000x800x600 max.,

1 camera/vision inspection machines,

1 automatic 300x200x30 imaging dimensional measurement system,

Measuring column,

Hardness check.

-

Faro 3D measuring device -

Profile projector -

Profile projector -

Profile projector -

Three-dimensional measurement -

Three-dimensional measurement -

FPI lines -

FPI lines